Concrete forms have taken a new shape-and purpose. Insulating concrete forms (ICFs) are rigid plastic foam forms that hold concrete in place during curing and remain in place afterwards to serve as thermal insulation for concrete walls. The foam sections are lightweight and result in energy-efficient, durable construction.

ICFs consist of insulating foam, commonly expanded polystyrene (EPS) or extruded polystyrene (XPS). The three basic form types are hollow foam blocks, foam planks held together with plastic ties, and 4 x 8 panels with integral foam or plastic ties. ICFs can be used to form various structural configurations, such as a standard wall, post and beam, or grid. They provide backing for interior and exterior finishes.

Insulation values of ICF walls vary depending on the material and its thickness. Typical insulation values range from R-17 to R-26, compared to between R-13 and R-19 for most wood-framed walls. The strength of ICF structures relative to lumber depends on configuration, thickness, and reinforcement. However, ICF walls are designed as reinforced concrete, having high wind and seismic resistance.

There are many ICF wall types. Products are differentiated based on the type of form and the shape of the concrete sections. Products are further differentiated by how forms attach to each other, how finishes are attached to the wall, insulating values, foam types and other features.

Multi-Story Building, ICF Exterior Wall Infill for Flat Slab Concrete Structure. Condominium Complex, FL

Basic Material Used:

Insulated concrete forms (ICFs) are hollow, lightweight forms manufactured

using two 21/2 inch (63.5m), 1.5lbs/cu.ft density expanded polystyrene (EPS) panels

which are connected by uniquely designed, high impact polypropylene webs. During

construction, the forms are stacked then filled with concrete making stable, durable

and sustainable walls.

The following are basic components of ICF system,

Basic Components of ICF System

§ Formwork (Stay-In-Place)

¢ Plastic

¢ Expanded Polystyrene

¢ Extruded Polystyrene

§ Concrete (Cast-In-Place)

§ Steel reinforcement

Building Code Acceptance

U.S. Code Acceptance

ICFs must meet standard prescriptive structural design requirements for cast-in-place concrete walls in the building codes. The plastic foam insulation on the interior surface requires special attention to meet fire resistance provisions. The International Residential Codes (IRC) contains prescriptive methods for building below- and above-ground walls. In February 2003, the International Code Council Evaluation Service (ICC-ES) was formed and issues ICC Evaluation Reports. The ICC also maintains Legacy Reports issued by the former four building product evaluation services.

Code Adoption Status and the Prescriptive Method

In May of 1998, the NAHB Research Center completed work on the Prescriptive Method For Insulating Concrete Forms In Residential Construction (Prescriptive Method) which was funded by the Department of Housing and Urban Development (HUD), the Portland Cement Association (PCA), and the National Association of Home Builders (NAHB). The first edition of the Prescriptive Method served as the source document for building code provisions in the International Residential Code (IRC).

The second edition of this Prescriptive Method was published in January 2002, and expanded on the first edition by adding provisions for Seismic Design Categories C and D (Seismic Zones 3 and 4). Wall construction requirements, using Grade 60 reinforcing steel and concrete mixes with selected compressive strengths, were included. In addition, tables throughout the document were simplified.

The Prescriptive Method includes definitions, limitations of applicability, below-grade and above-grade wall design tables, lintel tables, construction details, various construction and thermal guidelines, and other related information for home builders, building code officials, and design professionals. A prescriptive approach to ICF design eliminates the need for engineering in most applications. The provisions of this document were developed using accepted engineering practices and practical construction techniques. However, users of the document should verify compliance with local code requirements. The Prescriptive Method includes provisions for majority of ICF systems including flat panel and plank systems and grid systems (waffle and screen).

The first edition of the Prescriptive Method was accepted for inclusion in the 2000 International Residential Code (IRC). The IRC includes provisions for the use of ICFs in both above- and below-grade applications. Bear in mind that the IRC is a model code. By regulation or legislation, States or localities will adopt provisions of the IRC and IBC. However States or localities adopt, they have the option to add or remove requirements as they see fit.

Local Code Issues/Barriers

Potential issues or barriers for the use of ICFs may be encountered, and include the following items:

§ General unfamiliarity of code officials and inspectors with the product

§ Fire issues due to the use of foam

§ Termites and the use of foam below-grade

§ Structural concerns, especially for high loads due to backfilling, wind, earthquake; special constructions; attachment/integration of walls, floors, roofs; and proper filling of forms with concrete

§ Moisture protection

§ Attachment of finishes

Builders should consult with the ICF manufacturers and local code officials to resolve any code issues.

Structural Design of ICFs Covered by Prescriptive Method

Where the IRC and Prescriptive Method are not yet accepted, when certain ICF types are not covered by the Prescriptive Method, or when buildings do not meet the applicability limits of the Prescriptive Method, engineered designs (usually with sealed sets of plans) may be necessary in order to obtain building permits. For systems and applications that are not covered by the requirements in the Prescriptive Method, the NAHB Research Centre, under sponsorship of the Portland Cement Association (PCA), completed the publication entitled Structural Design of Insulating Concrete Form Walls in Residential Construction. This publication, available from PCA, is a guideline for the design of single- and multi-unit residential structures using ICF wall systems. It includes step-by-step design procedures for ICF, a comprehensive design example, and many design aids, such as graphs, charts, and tables, to assist design professionals.

Most ICF manufacturers have taken steps of their own to have their proprietary systems approved by various model code organizations. Evaluation Reports produced by code bodies are available from those manufacturers. Most ICF manufacturers will also provide design services if necessary.

Applicability Limits for the ICF Prescriptive Method

ATTRIBUTE | MAXIMUM LIMITATION | |

General | Number of Stories | 2 stories above grade plus a basement |

Design Wind Speed | 150 mph (241 km/hr) 3-second gust (130 mph (209 km/hr) fastest mile) | |

Ground Snow Load | 70 psf (3.4 kPa) | |

Seismic Design Category | A, B, C, D1, and D2 (Seismic Zones 0, 1, 2, 3, and 4) | |

Foundations | Unbalanced Backfill Height | 9 feet (2.7 m) |

Equivalent Fluid Density of Soil | 60 pcf (960 kg/m3) | |

Presumptive Soil Bearing Value | 2,000 psf (96 kPa) | |

Walls | Wall Height (unsupported) | 10 feet (3 m) |

Floors | Floor Dead Load | 15 psf (0.72 kPa) |

First-Floor Live Load | 40 psf (1.9 kPa) | |

Second-Floor Live Load (sleeping rooms) | 30 psf (1.4 kPa) | |

Floor Clear Span (unsupported) | 32 feet (9.8 m) | |

Roofs | Maximum Roof Slope | 12:12 |

Roof and Ceiling Dead Load | 15 psf (0.72 kPa) | |

Roof Live Load (ground snow load) | 70 psf (3.4 kPa) | |

Attic Live Load | 20 psf (0.96 kPa) | |

Roof Clear Span (unsupported) | 40 feet (12 m) |

Standard Sizes of ICF Blocks

With the help of ICF system we can construct the concrete walls of different thickness. The standard sizes available in the market are 4", 6", 8" and 10" concrete core thickness.

Typical Straight ICF Block (6˝ Shown)

Cross section of ICF blocks

Side View of ICF Straight Block Showing Web Flanges

Side View of Straight Block Showing Top and Bottom Interlocking System

Types of ICF Systems

ICF are basically forms for poured concrete walls that stay in place as a permanent part of the wall assembly. The forms, made of foam insulation, are either pre-formed interlocking blocks or separate panels connected with plastic ties. The left-in-place forms not only provide a continuous insulation and sound barrier, but also a backing for drywall on the inside, and stucco, lap siding, or brick on the outside.

Although all ICFs are identical in principle, the various brands differ widely in the details of their shapes, cavities and component parts. Block systems have the smallest individual units, ranging from 8" x 1'4" (height X length) to 1'4" x 4'. A typical ICF block is 10" in overall width, with a 6" cavity for the concrete. The units are factory-moulded with special interlocking edges that allow them to fit together many like plastic children blocks.

Panel systems have the largest units, ranging from roughly 1' x 8' to 4' x 12'. Their foam edges are flat, and interconnection requires attachment of a separate connector or "tie." Panels are assembled into units before setting in place - either on-site or by the local distributor prior to delivery.

Plank systems are similar to panel systems, but generally use smaller faces of foam, ranging in height from 8" to 12"and in width from 4' to 8'. The major difference between planks and panels is assembly. The foam planks are outfitted with ties as part of the setting sequence, rather than being pre-assembled into units.

Within these broad categories of ICFs, individual brands vary in their cavity design. "Flat wall" systems yield a continuous thickness of concrete, like a conventional poured wall. "Waffle grid wall" systems have a waffle pattern where the concrete is thicker at some points than others. "Screen grid" systems have equally spaced horizontal and vertical columns of concrete which are completely encapsulated in foam. Whatever the differences among ICF brands, all major ICF systems are engineer-designed, code-accepted, and field-proven.

Three Major types of ICF Systems are,

Screen grid OR Post-and- Beam (1st Generation)

Screen grid OR Post-and- Beam (1st Generation)

Key Features of each system,

1. Screen grid OR Post-and- Beam (1st Generation)

Ø Post and Beam Arrangement

Ø Most Versatile Because of its Stability and Strength

Ø While structurally Stronger Actually Lighter in Overall weight than other ICFs, this Factor make Batter in Seismic Prone Zone.

Screen Grid ICF System

2. Waffle grid (2nd Generation)

Ø Closely Spaced vertical and Horizontal members with a concrete web between Members.

Ø Structurally Strong

Waffle Grid ICF System

3. Flat ICF System (2nd Generation)

Ø Flat wall ICF are System In Which the concrete within the form is uniform thickness throughout.

Ø It Requires Substantial Amount of Bracing.

Ø Ease to Pour Concrete

Ø Ease for the Lintel design Also

Flat ICF System

Manufacturer of ICF Systems

Tools for Block Installation

§ Hand saw, folding pruning saw or conventional rip saw

§ Portable power saw

§ Keyhole saw

§ Table saw (optional)

§ Tape measure

§ Cordless driver drill and appropriate bits

§ Hammer drill

§ Reinforcing steel tie tools

§ Hammer

§ Framing square

§ 2 ft Spirit Level

§ 6 ft Spirit Level

§ Laser level, water level, or transit

§ Plumb bob

§ Mason's line (Enough to circle entire structure)

§ Chalk line

§ Foam gun

§ Reinforcing steel bender and cutter

§ Scaffold planks

§ Wall alignment & bracing system

§ Steel Stakes to anchor alignment braces (n/a if bracing off a slab)

Tools for Concrete Pour

§ Concrete Vibrator, 1 inch to 11/4 inch (25 to 32mm) head

– 10 to14 ft (3 to 4.2m) flexible shaft

§ Rubber gloves

§ Hard hats

§ Concrete finishing tools

§ Flat shovels for spill cleanup

Tools for Utility Installation

§ Hot Knife (for electric box cutout)

§ Electric chain saw (for cutting Romex wiring and plumbing channels)

§ Foam gun & Foam

Materials list

§ Reinforcing steel as required and accessories, e.g. ties, stirrups.

§ Screws to attach alignment bracing to ICF blocks (15/8 inch, 21/2 inch, #10 coarse thread)

§ Concrete Screws 11/2 to 13/4 inch to attach foot of alignment braces to concrete slab (TAPCON brand or equivalent)

§ Material for rough openings (i.e. 2x10, 2x6, etc.) lumber or plywood for fabricating wood bucks or vinyl bucks

§ Tie wire in rolls and in pre-made reinforcing steel tie loops

§ Anchor bolts, nuts, and washers or Simpson Strong-tie® ICFLC ledger connectors

§ Sleeves for mechanical and/or electrical fixtures

§ OSB or plywood for bridging cut joints, or removed webs, block outs for anchor bolts, etc.

§ Foam 2 Foam® EPS controlled-expansion foam/adhesive

§ Waterproofing / Damp Proofing system

10 Step Construction Guide

Step 1 –

Plan the outline of the block and the location of door and window openings on a conventional footing or a slab that is level, straight and square. Reinforcing steel dowels should extend upward from the footing into the cavity of the block or as per engineering and/or local code requirements.

Outlining walls

Step 2-

Place the first corner blocks on each corner, then lay the straight blocks toward the centre of each wall segment. On the first course, use zip-ties or wire ties on the webs to connect the blocks and pull them snugly together. Following this,install horizontal steel reinforcement by placing it in the clips at the top of the internal webs within the block cavity. The clips hold the reinforcing steel securely and eliminate the need for wire tying. (Repeat this process for each course of block).

Placing Corner Blocks First Installing Horizontal Reinforcing Steel And Lap Splicing

Step 3 –

Install the second course of ICF by reversing the corner blocks, so that the second course of block is offset from the first, in a running bond pattern. At this point check for level across all of the blocks. If the courses are not level, use shims or trim the block as required.

Installing Second Course of ICF

Step 4 –

Install window & door frames ("bucks") at each location where an opening is required; cut and fit the ICF blocks around them. Bucks are used to hold back the concrete and stay in place permanently providing a nailing surface for the installation of windows and doors. Pressure-treated lumber or vinyl bucks may be used.

Installing Window and Door Bucks

Step 5 –

Install additional courses of block by continuing to overlap the courses so that all joints are locked both above and below by overlapping blocks.

Continuing Installing Block Courses

Step 6 –

Install alignment bracing around the entire wall of the structure to ensure that the walls are straight and plumb and to enable alignment adjustment before and during the pour. The bracing also serves the dual purpose of providing a secure and safe framework to support scaffolding planks once five courses have been stacked.

Installing alignment and bracing system around the perimeter of the wall

Step 7 –

Stack the block to the full wall height for single storey construction, or to just above floor height for multi storey construction. Cut the vertical reinforcing steel to length and begin installing it from the opening at the top of the wall, through the spaces between the horizontal reinforcing steel.

Install Vertical Reinforcing Steel after Top Course Of Blocks

Step 8 –

Pour the concrete into the stacked walls using a boom pump. Do this in lifts approximately 3-4 ft (0.9-1.2m) at a time, circling the structure until the top of the wall is reached. Next, use a mechanical pencil vibrator (stinger) to vibrate the concrete and remove all air pockets within the wall. Up to one story can be poured each day using this method.

Pouring concrete in lifts of 3-4 ft (0.9-1.2m)

Step 9 –

Screed off the concrete until it is even with the block top and then "wet set" anchor bolts into the concrete top. These bolts will be used later to install the top plate (mud sill) for the installation of rafters or trusses.

Wet Set Anchor Bolts in Top Course Of Upper Floor

Step 10 –

Remove bracing after the concrete has cured, then proceed with further stages of construction.

Steel Reinforcement for Walls

Overview

Building any structure using ICFs requires the installer to have a good knowledge of the fundamentals of steel reinforcement. This part of the manual will discuss the basics of reinforcing steel requirements for ICF walls.

Plan Requirements

The designer (Architect/Engineer) of any project should clearly indicate the following information on his plans:

1. Separate cross sections of all walls using ICF. Each cross section

should clearly show the size of ICF block used (i.e. 4, 6, 8, or 10 inch)

for the building inspector and installer.

2. Each cross section should show the wall heights involved for every storey.

3. Vertical and horizontal reinforcing steel bar sizes, spacing and grade of steel

should be clearly marked for every storey in each wall cross section or in a

separate note on other sheets.

4. The placement of reinforcing steel, especially the vertical ones should be

clearly marked (i.e. off center or towards interior/exterior or centered in

the wall).

5. The designer should specify the lap splice type and lengths for every section

of the wall where splicing is anticipated.

The Purpose of Reinforcing Bars

Reinforced concrete structures are composed of two different materials;

a. Concrete

b. Steel

Plain concrete is a strong material in compression. Compressing a plain concrete cube or cylinder requires a relatively large amount of compressive force before reaching

compression failure. However plain concrete is relatively weak in tension (typically can only carry one tenth (1/10) of its compression strength in tension).

Reinforcing steel has excellent strength in both compression and tension loads but ismore expensive than concrete.

Therefore reinforced concrete structures are typically designed by engineers such that concrete is mainly utilized for most of the compressive forces and reinforcing steel is

utilized for all of the tensile forces and in some cases some of the compressive forces. The design of reinforced concrete structures have been streamlined particularly over the last century for safety as well as economic feasibility. Reinforced concrete structures have had a tremendous track record in some of the most complicated structures including dams, bridges and high rise buildings across the globe.

Horizontal Reinforcement

ICF polypropylene webs are specifically designed to accommodate and secure the horizontal reinforcing steel in place without the need to tie them. Typically the first course of horizontal reinforcement is placed in the notches closer to the EPS panel. The second course of horizontal reinforcement is staggered so that it is placed in the notch towards the center of the concrete wall. The third course is placed in the same position as the first course. The fourth course is placed in the same position as the second. This staggered pattern of horizontal reinforcement is necessary to allow for the vertical reinforcement to be placed from the top and weave in between the horizontal steel bars.

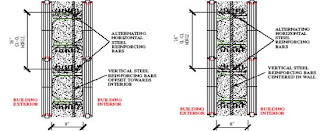

Figures below show typical vertical and horizontal reinforcing patterns for below grade and above grade applications using 8" ICF block respectively.

Typical below grade Typical above grade

Typical below grade Typical above grade

reinforcing steel placement reinforcing steel placement

Reinforcement for Wall Openings

Most walls will have window or door openings or both. Creating a wall opening in a reinforced concrete wall creates extra stress around that opening especially at the corners. Window and door headers also known as lintels can be subjected to significant bending moment and shear forces depending on several factors. Please refer to Appendix A for more details on how to handle reinforcement in wall openings.

Reinforcement Splicing

Steel reinforcement typically comes in 20 foot (6 meter) lengths. In such cases where steel reinforcement is required to exceed this length, then a splice is required. The main purpose of the splice is to transform the stresses whether tensile or compression from one steel reinforcing bar or a group of bundled bars to another in a manner to satisfy the governing local building/engineering codes and/or requirements of engineering plans and specs.

Steel Reinforcing Bars and Jobsite Safety

Unguarded protruding steel reinforcing bars are hazardous and can result in injury or death. The following measures greatly reduce the hazards of exposed reinforcing steel:

• Guard all protruding ends of reinforcing steel bars with caps or wooden

troughs, or

• Bend reinforcing steel so exposed ends are no longer upright.

•When employees are working at any height above exposed rebar, fall

protection/ prevention is the first line of defence against impalement.

Plastic Mushroom Caps on Protruding Steel Bars

Interior and Exterior Finish

Interior Drywall

Currently all building codes in North America require foam plastics to be separated from the interior living spaces, any habitable spaces and some crawl spaces by a thermal barrier (fire protection) that will remain in place for 15 minutes based on specific testing criteria.The most common type of interior finish material that will meet the thermal barrier requirements as stipulated by the building codes is a 1/2 inch (12.7mm) gypsum board also known as Drywall®.

The Amvic ICF polypropylene webs provide a horizontal and vertical furring strip to which the Drywall® can be directly attached. The spacing and size of the screws should follow the local building code requirements. Drywall sheets can be installed vertically or horizontally.For the purpose of meeting the building code requirements regarding Drywall® installation, Amvic has conducted the following tests which are available upon request:

1. Drywall type "S" fine thread and type "W" coarse thread screw pullout and shear in accordance with ICBOES AC 116 in conjunction with ASTM D1761.

2. Room fire test standard in accordance with UBC-1997 standard 26-3 for protection of interior foam plastics using 1/2 inch (13mm) gypsum board.

3. Fire test in accordance with CAN/ULC S101-04 and ASTM E119-00a "Standard test methods for fire tests of building construction and materials using 1/2 inch (12.7mm) gypsum board.

Traditional Stucco (Exterior)

Stucco is a cement based wall cladding system that can be used as an exterior or

interior finish. Traditionally stucco is applied over wood stud with sheathing, cast in place concrete or masonry substrates. Modern stucco applications have advanced and adapted to other substrate materials including Amvic ICF.

Stucco cladding for insulating concrete forms is mainly composed of metal wire lathe, a base coat and a finish coat. The metal wire lathe is attached to the Amvic propylene webs using approved drywall fine thread or coarse thread screws.

Typical Stucco Application Over ICF

Currently there are two main types of stucco used in North America:

Three Coat Stucco

The stucco base itself is applied in two coats and followed by a third coat. Each of the two base coats is typically 3/8 inch (10 mm) thick resulting in a finish stucco base of 3/4 inch (20 mm).

The first base coat is known as scratch coat. This coat keys into the metal wire lathe, covering it completely. Horizontal and vertical grooves are introduced in this coat as it cures. The grooves will provide a good gripping surface for the coat to follow. The second base coat is known as the brown coat. It is keyed into the grooves in the scratch coat and is often smoothed in preparation for the final coat.

One-Coat Stucco

The stucco base is applied in a single coat or 3/8 – 5/8 inch (10 – 16 mm) thick. A finishcoat is then applied.

Stucco finish coats can have a variety of textures and colors and generally produce a pleasing look.

EIFS (Exterior Insulation & Finish System)

EIFS (also known as synthetic stucco) is a multi-component exterior finish for walls. The system has traditionally been installed over wood frame substrates with appropriate sheathing. Some EIFS manufacturers have changed the name of their products to distinguish it for ICF application e.g. Dryvit® EIFS products for ICF has changed to TAFS (Textured Acrylic Finishing System)

The typical EIFS cladding system consists of:

1. Foam Insulation Layer

2. A polymer base coat

3. Fiber mesh reinforcing layer embedded in the polymer base

4. Acrylic, Textured finish coat

Typical EIFS installation over ICF

The EPS that makes up the Amvic ICF panels is a suitable substrate for applying EIFS cladding directly without the need for an additional foam board.

EIFS wall claddings, like stucco, have many textures and colors that can be applied to the finish acrylic coat to produce the desired architectural effect.

EIFS finish

Anchored Masonry Veneer

Masonry or brick veneer can be applied to Amvic ICF wall in the same manner as

regular wood frame or steel stud construction. A ledge support is required to carry the

masonry veneer gravity loads (Please refer to part 9.5 of the manual). The masonry

veneer ties shall be screwed directly to the Amvic polypropylene webs using approved

fine thread or coarse thread screws. The horizontal and vertical spacing of the

masonry veneer ties shall comply with engineering and/or local building

requirements. Amvic has retained a consulting engineering firm to prepare an

engineering analysis report on masonry veneer ties under different wind and seismic

load conditions. A copy of the report is available upon request and can also be

downloaded from our website. (Amvic Masonry Ties Structural Report.)

Wood,Vinyl, and Fiber Cement Siding

Amvic ICF can also be finished with exterior siding planks such as wood, vinyl and

fiber cement.

For wood and fiber cement siding products, wood or metal strapping will have to be installed on the Amvic EPS surface by screwing directly to the block propylene webs.

The wood or fiber cement siding can then be installed over the strapping using

approved nails or screws.

Vinyl siding in most cases can be installed by directly screwing into the Amvic ICF

propylene webs with no furring straps.

ICF Advantages ……

Concrete Homes save Energy

Building a concrete home with insulating concrete forms (ICFs) saves energy and money. The greater insulation, tighter construction, and temperature-smoothing mass of the walls conserve heating and cooling energy much better than conventional wood-frame walls. This reduces monthly fuel bills. It also allows use of smaller heating and cooling equipment, saving money in construction. |

|

Houses built with ICF exterior walls require an estimated 44% less energy to heat and 32% less energy to cool than comparable frame houses. A typical 2000 square foot home in the center of the U.S. will save approximately $200 in heating costs each year and $65 in air conditioning each year. The bigger the house the bigger the savings. In colder areas of the U.S. and Canada, heating savings will be more and cooling savings less. In hotter areas, heating savings will be less and cooling savings more

|

Comfort and Quiet with Concrete Homes |

Concrete walls built with insulating concrete forms effectively buffer a home's interior from the outdoors. The thick ICF sandwich of a massive material (concrete) with a light one (foam) sharply cuts fluctuations in temperature, air infiltration, and noise. They keep the inside of a house more comfortable and quiet than ordinary wood frame walls. |

|

Where does the greater comfort come from? |

ICF walls increase comfort in three ways: |

|

The continuous layer of foam insulation along the ICF wall helps keep the temperature the same everywhere. It virtually eliminates the "cold spots" that can occur in frame walls along the studs or at gaps in the insulation. |

|

|

The heavy concrete of the ICF wall gives it the heat-absorbing property of "thermal mass". This smoothes out swings in temperature over time. So the house does not tend to overheat or get suddenly chilly as the furnace or air conditioner cycles on and off. |

|

|

The interlocking foam faces, sealed with continuous concrete in the center, make ICF walls exceptionally airtight. So drafts are cut sharply. In tests, homes built of ICFs had only about one-third to one-half as much air infiltration as the typical frame house. |

|

Greater Strength

– Storm resistant - rated for a 250MPH wind load

– Blast Tested [Force Protection Equipment Demonstration (FPED V) April 26–28, 2005]

Better Fire Protection

– UL listed at 3 hours with ½" drywall; 4 hours with 5/8" type x gypsum

Quieter

– Sound Transmission Class rating of 50 or greater

Reduced Maintenance

– Conventional construction is prone to maintenance problems such as drywall pops and basement leaks

Resistant to pests

– ICFs provide no food source and contain nothing to attract termites and other pests

Resistant to mold

– the concrete, foam and steel in an ICF wall are not a food source for mold growth, unlike wood and other organic materials; the airtight nature of the ICF structure also provides for better moisture control, further reducing the chance for mold to occur

No comments:

Post a Comment