Pavement design and Structure

General points regarding design of pavement

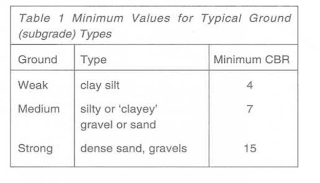

• Quality of sub grade is often measured by special test known as CBR. Moisture content and density of materials will change the CBR values.

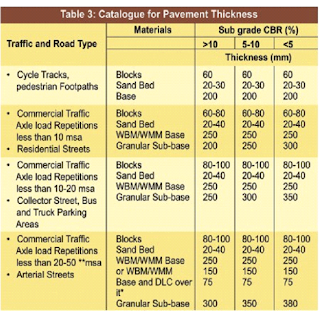

• Depending upon the traffic loading and ability of sub grade to carry the load, the thickness of sub base or base course is decided.

• The base course thickness can vary with the design conditions from 0 to 300 mm but most widely used are 75 mm to 200 mm.

• Before starting of construction two other aspects materials and drainage are required to be considered

Advantages of ICBP

• Mass production, ensures availability of block having consistent quality and high dimensional accuracy

• Good quality blocks ensures durable pavement when constructed as per design and specification

• ICBP tolerates higher deflections without structural failure, will not get affected by thermal expansion and contraction

• ICBP does not require curing and hence pavement can be put into service immediately

• Construction of pavement is labour intensive and requires very few equipments.

• The system provides ready access to underground utilities without damage to pavement.

• Maintenance of ICBP pavement is easy and simple

• Use of coloured blocks facilitates permanent markings.

• Low life cycle cost

• Provides resistance to punching loads and horizontal shear force caused by movement of heavy vehicles.

Limitations of ICBP

• Quality control of block at the factory premises is very much necessary

• Any deviations of base course profile will get reflected on ICBP. Hence proper supervision is required.

• High quality, graded coarse sand and joint filling sand are essential for good performance

• ICBP over unbound granular base course is susceptible to the adverse effects of poor drainage and will deteriorate faster

• ICBP is not suitable for high speed roads (Speeds over 60 Km/Hr)

Applications of ICBP Technology

• Non traffic areas - Building premises, Footpaths, malls, Pedestrian plaza, Monument premises, Public gardens/Parks, Shopping complex, Parking areas, and railway platforms

• Light traffic - Car park, Office driveway, Housing colony roads, rural roads, Residential colony roads, Farmhouses etc.

• Medium traffic - City streets, small market roads, Intersection, Low volume roads, Service stations etc.

• Heavy and Very heavy traffic – Container, Bus terminals, Port/Dock areas, Roads in Industrial buildings, Airport pavement

Materials- Paver Block

• Produced with zero slump concrete

• Available in different shapes and colours.

• Quality of the block will depend upon capacity of compaction, grade of cement used, water content, quality of aggregates used and their gradation and mix design, admixtures used, handling equipments used, curing method adopted, level of supervision during production, workmanship and quality control achieved etc.

• Specification of materials used for preparation of block, physical test method, sampling and acceptance criteria has already been formulated in IS 15658:2006, & IRC SP 63:2004

Shapes and colours for paving block

• Type A – Paver block with plane vertical face, which do not key into each other when paved in any pattern.

• Type B – Paver block with alternating plain and curved/corrugated vertical face, which key into each other along the curved/corrugated vertical face when paved in any pattern .

• Type C – Paver block having all faces curved/corrugated which key into each other along all vertical faces when paved in any pattern

• Type D – ‘L’ & ‘X’ shaped paver block which have all faces curved or corrugated and which key into each other along all vertical faces when paved in any pattern

Bedding and Joint filling sand

• The selection of material as bedding and joint filling sand is very vital.

• Joint filling sand must be relatively finer than the bedding sand.

• It is necessary to restrict the fines (clay and silt) to 10 % in joint filling sand.

• Don’t used cement to fill the joints.

• Joint filling sand must be dry.

Base and Sub base materials

• Base and sub base material requirements will depend upon traffic loading expected and sub grade strength.

• Grading- For better interlock and ease of construction, Number of broken faces - For better interlock, Crushing resistance- to prevent breaking of stone particles, Soundness- For durability, Nature and quantity of fine particles in the aggregate or sand, desired drainage characteristics are need to be considered.

• Factors like local availability, economy, climatic and environmental factors will detect the selection of materials

• Commonly used materials are

– Unbound crushed rock

– Water bound macadam

– Wet mix macadam

– Cement bound crushed rock

– Lean cement concrete

• Quality of sub base material should be in conformance with IRC-37.

• Commonly used materials for sub base are

– Cement treated gravel

– Sand

– Stabilized materials

Sequencing of operations for ICBP

• Step 1 - Installation of sub surface drainage works

• Step 2 - Leveling and Compaction of sub grade

• Step 3 - Provision and Compaction of Sub base course (When needed)

• Step 4 - Provision and Compaction of base course & Checking of correct profile

• Step 5 - Installation of edge restraints

• Step 6 - Provision and Compaction of coarse bedding sand

• Step 7 - Laying of blocks and interlocking

• Step 8 - Application of joint filling sand and compaction

• Step 9 - Cleaning the surface

• Step 10 - Filling any remaining empty portions in the block layer especially near edge restraints block with in situ concrete.

Step 1 - Installation of sub surface drainage works

• Normally drains are sub surface drains and must be surrounded by either filter aggregate or geotextiles to avoid washing of bedding and joining sand.

• Except pedestrian open areas the pavement surface should have a cross fall of at least 3 % and top of the blocks next to drainage channels should be at least 10 mm above lip of the channel.

• In pedestrian open areas the pavement surface should have a cross fall of at least 1.25 % and top of the blocks next to drainage channels should be at least 3 mm above lip of the channel.

Step 2 - Leveling and Compaction of sub grade

• Importance of sub grade

• Importance of compaction of sub grade

• Compaction near trenches, back fills etc.

• The preparation of sub grade should be graded to a tolerance of ± 20 mm of design levels and its surface evenness should have tolerance of 15 mm under a 3 m straight edge

• Moisture content in the sub grade material will affect the strength. Hence water table should not be at a level of 600 mm or higher below the sub grade level. In case of soils like clay and silt moisture must be removed before further rolling. After that it is covered with a thin layer of dense base course. The layer is then rolled.

• Stabilization of sub grade with lime or cement may also increase the strength of sub grade.

• Sub grade should be compacted in layers either 150 or 100 mm thickness as per IRC guidelines

Step 3 & 4 Provision and Compaction of Base and Sub base course & Checking of correct profile

• Base course and Sub base course are required to be constructed with IRC:SP:49-1998, IRC:SP:50-1973, IRC:SP:63-1976, IRC:19-1997, IRC:37-2001.

• Quality control specified in IRC:SP:11 for construction of lower layers.

• The base course is directly laid over the sub grade with the thickness of each layer should not be more than 100 mm compacted thickness.

• For weaker sub grades there are other options

– Improved drainage

– Cement of Lime stabilization

– Use of Geotextiles

• Base course should be finished within +0 mm to -10 mm for level. It should not pond water and should be well shaped. Do not rely on sand bedding for removal of unevenness

• For compaction usually vibratory plate compactors are used. The selection of vibratory plate compactors is very vital.

• Number of passes for effective compaction will depend upon the various factors like compactor capacity, speed of compactor, base course material properties, moisture content and layer thickness.

• Normally vibratory compactors will loose top material of base course and hence after applying the required number of passes, 4 passes of regular roller or plate compactor without vibratory motion should be given

• The compaction of material around manholes, kerbs, service boxes must be done carefully.

Step 5 - Installation of edge restraints

• Must be produced with high quality concrete with at least 28 day characteristic compressive strength of 30 N/mm2 and Flexural strength 3.8 N/mm2

• Road kerbs, Edge strips, PCC of 150 mm X 150 mm can also be used as edge restraints

• The gap between the two edge restraint block is required to be closed with cement mortar of 1:6 proportion.

Step 6 - Provision and Compaction of coarse bedding sand

• Thickness of bedding sand in loose form must be 25-50 mm and in compacted form 20-40 mm.

• Sand must be laid in uniform thickness

• Grades and cambers must provided in the sub grade and base course it self and not in the bedding sand.

• Sand is required to be spread with screed board

• Bedding sand must have uniform moisture content of 6 to 8 %. Hence regular checking of moisture content in sand is important.

• Before placing the sand take a trial to decide the surcharge for a typical sand.

• Required quantity of sand for a days work must be stored in advance and must be covered with tarpaulin sheets or any other suitable material.

• After laying proper compaction of bedding sand is required

Step 7 - Laying of blocks and interlocking

• Block should be laid on 5 mm screed provided with bedding sand material

• Don’t place block on compacted or saturated sand

• Normally laying should commence from edge strip and proceed towards centre. Also as far as possible laying should be done only from one direction along the entire width of the area paved.

• While locating the starting line following points must be considered

– On a sloping site start from lowest point and proceed to up slope.

– In case of irregular shaped edge restrains or strips it is better to start from straight string line as shown in fig

• Gap between the two blocks are not less than 2 mm and not more than 4 mm. The blocks very popularly laid in three patterns

Step 8 - Application of joint filling sand and compaction

• Don’t use wet block and wet sand.

• Joint filling sand must be properly graded as per guidelines.

• For compaction vibratory plate compactors are used. Heavy plate compactors with a weigh between 300 to 600 kg and apply a centrifugal force in the range 30 to 65 KN are preferred over standard plate compactors (90 Kg Weight, 15 KN force, 0.3 m2 plate area)

• Alternative to this is apply 2 passes of standard plate compactor and then apply 2 to 6 passes of a roller, Vibrating roller (With static weight less than 4 tonne, amplitude less than 0.6 mm), Or Pneumatic tyre roller (6 tonne or heavier)

• There should not be delay in compaction after laying of paving blocks.

• The surface tolerance of individual layers must be as per table

No comments:

Post a Comment