Design and construction principles for top-down method primarily call for two major structural elements.

· Columns with sufficient capacity must be pre-founded in bored piles or barrettes to sustain the construction load and to utilize as part of bracing system.

· Excavation for basement must be carried out with the support of permanent

retaining wall so that basement floor slabs can be utilized as lateral bracing.

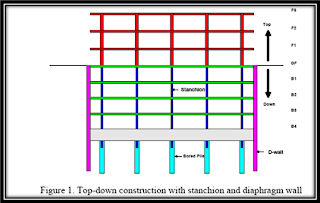

Diaphragm wall of 0.8m to 1.2m in thickness with sufficient embedment in firm soil layers is commonly used as a retaining wall whereas prefabricated steel columns known as Stanchions embedded in either large diameter deep-seated bored piles or barrettes are utilized as structural columns. Figure 1 illustrates the top-down construction method with utilization of stanchions and diaphragm wall.

Installation of Diaphragm wall

Construction of guide wall

A guide wall is constructed to set out the position of the diaphragm wall.

Excavation of panel

The grab/trench cutter cuts and removes the soil to form the panel. The excavation is stabilised by filling it with bentonite slurry to support the wall of the excavation.

Installation of Rebar cage and concreting

The crane lifts up the reinforcement-bar cage and places it within the panel. Concrete is poured into the panel to form the panel wall.

Repetition of process

Process 2 - 4 repeats for the remaining soil in between the panels till the entire length of the diaphragm wall construction is completed.

TYPES OF STANCHION AND THEIR APPLICATION

TYPES OF STANCHION

|

General information

| ||

Material & Example Size

|

Application

|

limitation

| |

Light stanchion

|

Steel H-beams

350x350x137kg/m

|

For semi top-down

construction

• For temporary decking

|

Limited capacity of light stanchion does not allow for construction of super

structure until completion of

basement construction

|

Medium sized stanchion

|

Steel H-beams

350x350x390 kg/m

|

For semi and full top-down

construction of shallow to

medium deep excavation

|

Limited number of super

structure floors construction

|

Heavy stanchion

|

Steel H-beams

508x457x738kg/m

• Composite steel columns

built up by 2 or more small

to medium size H-beams

• Large section pre-cast RC

column (seldom use)

|

Full top-down construction in

deep excavation

|

Depending on the loading

condition, numbers of

superstructure floors can be

constructed before

completing basement

excavation

|

STANCHION INSTALLATION METHODS

Stanchion installation method is usually selected by the piling contractor who takes into consideration three main factors such as installation depth, size of stanchion and size of bored or barrette piles. Though installation details may be different from one contractor to another, stanchion installation can be categorized under two main methods, post-concreting or plunging installation and pre-concreting installation or placing stanchion prior to concreting.

Post-concreting installation or plunging method

In this method, stanchion is installed immediately after completion of bored pile concreting process. General construction sequence involved in this method is demonstrated in Figure 2.

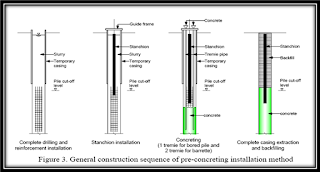

Pre concreting method

In this method, stanchion is installed immediately after completion of drilling and reinforcement lowering prior to concreting process. In some projects stanchion is attached to the last section of reinforcement and installed together with the reinforcement. General construction steps involved in this method are demonstrated in Figure 3.

Advantages and disadvantages

Advantages:

1. The shortened construction period due to simultaneous construction of the basement and the superstructure.

2. More operational space gained from the advanced construction of floor slabs.

3. The higher stiffness of floor slab compare to steel struts improves the safety of excavation.

4. It is highly suitable for construction for tall buildings with deep basements to be constructed in urban areas.

Disadvantages:

1. Higher cost (due to the construction of pile foundation)

2. Since the construction period of the basement is lengthened, the lateral displacement of retaining wall or ground settlement may possible increase due to the influence of creep if the soil layers are encountered.

3. The construction quality may influence because of worsened ventilation and illumination under floor slab.

4. It requires highly skilled supervision and labour force.

Case Study

a) The Top-Down Construction in Indonesia:

The top down construction in Indonesia was introduced for the first time in 1994. The project was the Bank Indonesia C-Building Projects (12 stories, and 3 basement), and PT. (Persero) Wijaya Karya was the main contractor.

In, 1995 another project was Menara Merdeka Building (30 stories, 3 basement) also built by top-down construction. The main contractor was joint operation of PT. (Persero) Pembangunan Perumahan and PT. (Persero) Wijaya Karya.

The largest project in Indonesia that use the top-down construction was Pasar Baru Bandung Project , 2003. The huge building was consisted 120,000 sq.m, 10 stories plus 3 basements, and the time line for accomplishing the project was only 8 months. The main contractor was PT. (Persero) Pembangunan Perumahan.

b) The one seen here depicts the basement entrance for the Cheung Kong Center projectin hong kong, which best illustrates the method. The top-down construction method is virtually the only method suitable for the construction of deep basements on a large scale. One irresistible advantage of this method is that substructure and superstructure work can be carried out at the same time.

C) Top-down basement construction: the permanent RC structure at the top has been completed but remains supported on temporary steel stanchions, while the excavation and construction work to the lower basement is yet to be continued. (Lee Gardens)

d) Another feature of top-down construction is that the ground floor slab (indeed, any slab close to ground level) is cast first as a starting level to provide the necessary rigidity to the side supports. This example, from the Festival Walk project, best illustrates the arrangement

Conclusion

From the above report we can conclude that top down constuction has its suitability for certain kind of mega structures. It is suitable for structures with deep basements like undergrond rails, car parks etc. It is also very efficient way of doing two way construction to save time. Skyscrapers with deep basements in urban areas should be constucted using top down construction. But top down construction needs very efficient planning and designing and skilled supervision and labour force. Top down construction is the need of the hour as it is highly time efficient and is becoming popular and is coming more and more in practice with every passing day.

No comments:

Post a Comment